BS5308 Cable Part 1 Type1 XLPE-OS-LSOH

Applications :

- The unarmoured LSOH versions (Part 1 Type 1) are generally use for indoor installation and suitable for wet and damp areas. Generally used within industrial process manufacturing plants for communication, data and voice transmission signals and services, Also used for the interconnection of electrical equipment and instruments, the LSOH sheath can reduce toxic smoke and fume emission.

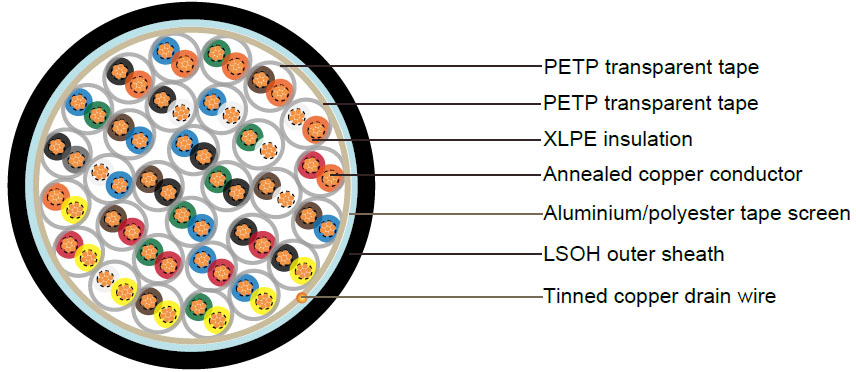

Construction :

-

Conductor Annealed or tinned copper, sizes: 0.5mm² and 0.75mm² mulitistranded(Class 5), 0.5 mm², 1.0 mm² solid(Class 1), 1.5mm² or 2.5mm², multistranded(Class 2) to BS6360 Insulation XLPE (Cross Linked Polyethylene), or PE (optional) Pairing Two insulated conductors uniformly twisted together with a lay not exceeding 100mm Colour code See technical information Binder tape PETP transparent tape Collective screen Aluminium/polyester tape is applied over the laid up pairs metallic side down in contact with

tinned copper drain wire, 0.5mm²Outer sheath LSOH(Low Smoke Zero Halogen) sheath Flame retardant to IEC60332-3-22 Fire resistant to IEC60331 Halogen free to IEC60754-1 Low smoke emission to IEC61034-1-2 Sheath colour Black or blue -

Mechanical and Electrical Properties :

- Operating temperature : -20˚C up to + 90˚C( fixed installation) ; 0˚C to +50˚C(during operation ).

- Minimum bending radius : 5 x overall diameter.

-

Conductor Area Size mm2 0.5 0.5 0.75 1.0 1.5 Conductor Stranding No. x mm 1 x 0.8 16 x 0.2 24 x 0.2 1 x 1.13 7 x 0.53 Conductor resistance max ohm/km 36.8 39.7 26.5 18.2 12.3 Insulation resistance min Gohm/km 5 5 5 5 5 Capacitance unbalance at 1 kHz(pair to pair screen) pF/250m 250 Max. Mutual Capacitance @ 1 kHz forNon OS or OS cables (except one-pair and two-pairs) pF/m 115 115 115 115 115 Max. Mutual Capacitance @ 1 kHz IS/OS cables (include 1 pair and 2 pair) pF/m 75 75 75 75 75 Max. L/R Ratio for adjacent cores(Inductance/Resistance) μH/ohm 25 25 25 25 40 Test voltage Core to core V 1000 1000 1000 1000 1000 Core to screen V 1000 1000 1000 1000 1000 Rated voltage max V 300/500 300/500 300/500 300/500 300/500

Parameter :

-

No.of

PairsNo.and Dia.

of WiresNominal Conductor Cross Sectional Area Nominal Radial Thickness of Insulation Nominal Thickness

of SheathNominal Dia.

of CableApprox.Weight no./mm mm2 mm mm mm kg/km 1 1/0.80 0.5 0.5 0.8 5.5 35 2 1/0.80 0.5 0.5 0.8 6.8 55 5 1/0.80 0.5 0.5 1.1 10.9 125 10 1/0.80 0.5 0.5 1.2 14.4 215 15 1/0.80 0.5 0.5 1.2 16.5 300 20 1/0.80 0.5 0.5 1.3 18.8 385 30 1/0.80 0.5 0.5 1.3 22.3 545 50 1/0.80 0.5 0.5 1.5 28.5 875 1 16/0.20 0.5 0.6 0.8 6.2 60 2 16/0.20 0.5 0.6 0.8 7.6 80 5 16/0.20 0.5 0.6 1.1 12.4 210 10 16/0.20 0.5 0.6 1.2 16.5 340 15 16/0.20 0.5 0.6 1.3 19.2 440 20 16/0.20 0.5 0.6 1.3 21.7 570 30 16/0.20 0.5 0.6 1.5 26.4 780 50 16/0.20 0.5 0.6 1.7 33.4 1130 1 24/0.2 0.75 0.6 0.8 6.7 75 2 24/0.2 0.75 0.6 0.9 8.4 100 5 24/0.2 0.75 0.6 1.2 13.8 250 10 24/0.2 0.75 0.6 1.3 18.4 450 15 24/0.2 0.75 0.6 1.5 21.1 600 20 24/0.2 0.75 0.6 1.5 24.4 920 30 24/0.2 0.75 0.6 1.7 29.5 980 50 24/0.2 0.75 0.6 2 37.6 1690 1 1/1.13 1 0.6 0.8 6.6 85 2 1/1.13 1 0.6 0.8 8 115 5 1/1.13 1 0.6 1.2 13.5 290 10 1/1.13 1 0.6 1.2 17.7 500 15 1/1.13 1 0.6 1.3 20.6 670 20 1/1.13 1 0.6 1.5 23.8 950 30 1/1.13 1 0.6 1.5 28.4 1030 50 1/1.13 1 0.6 2 36.6 1750 1 7/0.53 1.5 0.6 0.8 7.5 100 2 7/0.53 1.5 0.6 0.9 9.3 150 5 7/0.53 1.5 0.6 1.2 15.6 360 10 7/0.53 1.5 0.6 1.3 20.9 690 15 7/0.53 1.5 0.6 1.5 24.6 880 20 7/0.53 1.5 0.6 1.5 27.8 1230 30 7/0.53 1.5 0.6 1.7 33.7 1560 50 7/0.53 1.5 0.6 2 43 2400