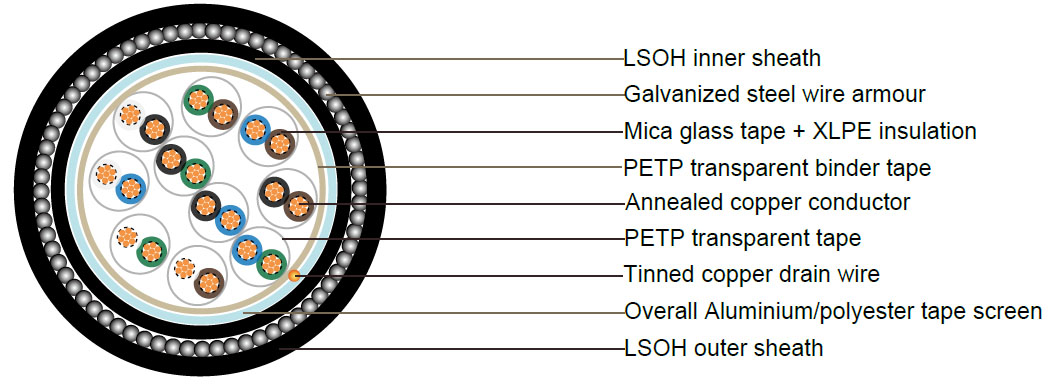

BS5308 Cable Part 1 Type 2 MG-XLPE-OS-SWA-LSOH

Applications :

- The armoured fire resistant versions (Part 1 Type 2) are typically used in chemical and process industries where there is danger of fire. The galvanised steel wire armour provides excellent protection.

Construction :

-

Conductor Annealed or tinned copper, Class 2 Insulation Mica glass tape, XLPE (Cross Linked Polyethylene),, or PE (optional) Pairing Two insulated conductors uniformly twisted together with a lay not exceeding 100mm Colour code See technical information Binder tape PETP transparent tape Collective screen Aluminium/polyester tape is applied over the laid up pairs metallic side down in contact with

tinned copper drain wire, 0.5mm²Inner Sheath LSOH(Low Smoke Zero Halogen) sheath Amour Galvanized steel wire armour Outer sheath LSOH(Low Smoke Zero Halogen) sheath Flame retardant to IEC60332-3-22 Fire resistant to IEC60331 Halogen free to IEC60754-1 Low smoke emission to IEC61034-1-2 Sheath colour Black or blue -

Mechanical and Electrical Properties :

- Operating temperature : -20˚C up to + 90˚C( fixed installation) ; 0˚C to +50˚C(during operation ).

- Minimum bending radius : 6 x overall diameter.

-

Conductor Area Size mm2 0.5 0.75 1.0 1.5 Conductor Stranding No. x mm 7 x 0.3 7 x 0.37 7 x 0.44 7 x 0.53 Conductor resistance max ohm/km 36 24.5 18.1 12.1 Insulation resistance min Gohm/km 5 5 5 5 Capacitance unbalance at 1 kHz(pair to pair screen) pF/250m 250 Max. Mutual Capacitance @ 1 kHz forNon OS or OS cables (except one-pair and two-pairs) pF/m 115 115 115 115 Max. Mutual Capacitance @ 1 kHz IS/OS cables (include 1 pair and 2 pair) pF/m 75 75 75 75 Max. L/R Ratio for adjacent cores(Inductance/Resistance) μH/ohm 25 25 25 40 Test voltage Core to core V 1000 1000 1000 1000 Core to screen V 1000 1000 1000 1000 Rated voltage max V 300/500 300/500 300/500 300/500

Parameter :

-

No.of Pairs No.and Dia. of Wires Nominal Conductor Cross Sectional Area Nominal Thickness of Insulation Nominal Thickness of bedding Nominal Dia. over Bedding Nominal Thickness of Armour Nominal Thickness of Sheath Nominal Dia. of Cable Approx. Weight no./mm mm2 mm mm mm mm mm mm kg/km 1 7/0.44 1 0.6 0.8 7.0 0.9 1.4 11.6 340 2 7/0.44 1 0.6 0.8 8.4 0.9 1.4 13.0 350 5 7/0.44 1 0.6 0.8 12.3 0.9 1.4 16.9 740 10 7/0.44 1 0.6 0.8 16.5 0.9 1.4 21.1 1150 20 7/0.44 1 0.6 0.8 21.4 0.9 1.4 26.0 1840 1 7/0.53 1.5 0.6 0.8 7.5 0.9 1.4 11.9 320 2 7/0.53 1.5 0.6 0.8 9.1 0.9 1.4 13.7 410 5 7/0.53 1.5 0.6 0.8 14.8 0.9 1.4 21.1 910