Portable Arc-Welding Cable 600V

Applications :

- These cables are designed for use as flexible welding leads connecting the electrode holder to the welding machine in the secondary circuit of electric arc welding systems.

Standards :

Construction :

-

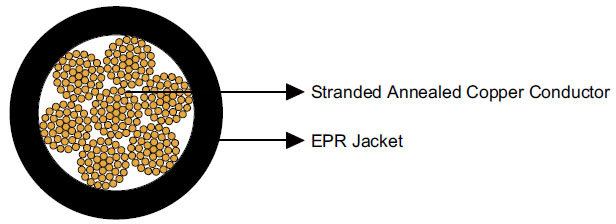

Conductor Class K/M stranded annealed copper conductor. Jacket Heavy-duty/medium-duty Ethylene Propylene Rubber (EPR).

Options :

- Other jacket materials such as NR/CSP/PCP/NBR/PVC are available upon request.

- Heavy-duty, two-layer jacket with reinforcement between the two layers can be offered as an option.

Mechanical and Thermal Properties :

- Minimum Bending Radius: 6×OD.

- Maximum Conductor Operating Temperature: +90℃.

Dimensions and Weight :

-

Construction No. of

StrandsNominal Insulation

ThicknessNominal Overall

DiameterNominal Weight Ampacity No. of cores

×AWG/kcmil- inch mm inch mm lbs/kft kg/km A 1×6 259 0.060 1.5 0.37 9.4 124 184 125 1×4 420 0.060 1.5 0.42 10.7 180 268 182 1×2 665 0.060 1.5 0.49 12.5 268 399 271 1×1 836 0.080 2.0 0.53 13.3 319 475 360 1×1/0 1045 0.080 2.0 0.59 14.9 415 617 444 1×2/0 1330 0.080 2.0 0.64 16.3 508 756 535 1×3/0 1672 0.080 2.0 0.70 17.8 628 934 667 1×4/0 2107 0.080 2.0 0.81 20.7 775 1153 809 1×250 2499 0.095 2.4 0.88 22.4 934 1390 1048 1×350 3458 0.095 2.4 1.01 25.6 1267 1885 1396 1×500 5054 0.095 2.4 1.18 30.0 1801 2680 1973