FIREROL Thin Wall Single Core Unsheathed Cables 300/500 V

EN 50306-2 (FRL-TW-05SU)

Application :

- -Used as signal and control cable for protected installations inside and outside of rail and transport vehicles, where space and weight are an important factor.

- -Used in cable harnesses, switchboards and control panels, driver desks etc.

Construction :

-

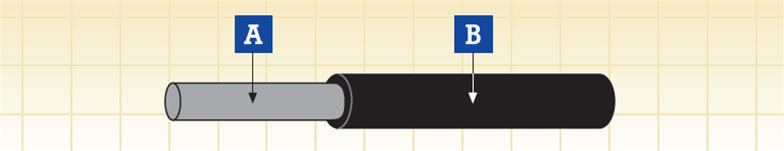

Conductor Tinned annealed copper wires as defined in EN 50306-2 Insulation LSZH special compound -

A. Conductor

B. Insulation

Electrical & Mechanical Properties :

-

Nominal Voltage 300/500 V Maximum Conductor Temperature 120°C /150°C (fixed installation) Minimum Permissible Ambient Temperature -25/-40°C (fixed installation) Bending Radius 3 x Overall Diameter

Chemical & Environmental Properties :

-

EN 60684-2 No fluorine EN 50305; EN 60811-2-1 Resistance to mineral oil & fuel oil, acid & alkali EN 50305 Resistance to ozone

Fire Performance for rolling stock application :

-

EN 50306-2 Hazard levels HL1, HL2/HL3, HL4 DIN 5510-2 Protection level 1/2/3/4 BS 6853 Interior use 1a, 1b, II; Exterior use 1a, 1b, II NF F 16-101 F0

Fire Performance for rolling stock application :

-

EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) Vertical flame propogation for a single insulated wire or cable EN 50266-2-4 + EN 50305; IEC 60332-3-24;

NF C 32-070 2.2 (C1); VDE 0472 Teil 804Vertical flame spread of vertically mounted bunched wires or cables EN 50268-2; IEC 61034-2; NF C 32-073 ;

NF C 20-902; NF F 16 101; VDE 0472 Teil 816Low Smoke Emission EN 50267-2-1; IEC 60754-1; NF C 32-074;

NF C 20-454; VDE 0472 Teil 815Halogen Free EN 50267-2-2/3; IEC 60754-2; NF C 32-074;

NF C 20-453; VDE 0472 Teil 813

Low Corrosivity (Acidity & Conductivity) EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853 Low Toxicity NF F 63 808; BS6853; NF F 16 101 Smoke index

FRL-TW-05SU 300/500 V :

-

Nominal

Cross-Sectional

AreaNumber X

Nominal

Diameter of

WireDiameter Min. Mean

Thickness

of InsulationOverall Diameter Weight Conductor

Resistancemin max min max 20℃ mm2 n X mm mm mm mm mm mm kg/km Ω/km 0.5 19 x 0.18 0.80 0.95 0.18 1.15 1.45 7 40.1 0.75 37 x 0.16(a) 1.00 1.15 0.18 1.35 1.65 8 26.7 1.0 37 x 0.18(a) 1.10 1.30 0.18 1.45 1.80 10 20.0 1.5 37 x 0.23(a) 1.45 1.65 0.22 1.95 2.30 20 13.7 2.5 37 x 0.30(a) 1.85 2.15 0.28 2.50 2.85 25 8.21 - (a) =This cable may be supplied in 19 strand conductor providing all product performance requirements in the specification are met.

|

|

|

|

|

|

Impact Resistant |

Highly Flexible |

UV Resistant |

Ozone Resistant | Abrasion Retardant |

Cold- resistant |

|

|

|

|

|

|

Resistance To Soldering Heat |

Acid&Alkaline Resistant |

IRM 903 Fuel Oil Resistant |

IRM 902 Mineral Oil Resistant |

Fire Retardant NF C32-070-2.2(C2) IEC60332-3-24/EN50266-2-4 |

Flame Retardant NF C32-070-2.1(C1) IEC60332-1-2/EN50265-2-1 |

|

|

|

|

Low Toxicity NF X70-100/NF F63 808 TM1-04/BS 6853 |

Low Corrosivity IEC60754-2/EN50267-2-2/3 NF C32-074/VDE 0472-813 |

Low Smoke Emission IEC 61034-2 / EN 50268-2 NF C32-073/VDE 0472-816 |

Zero Halogen IEC 60754-1/EN 50267-2-1 NF C32-074//VDE 0472-815 |