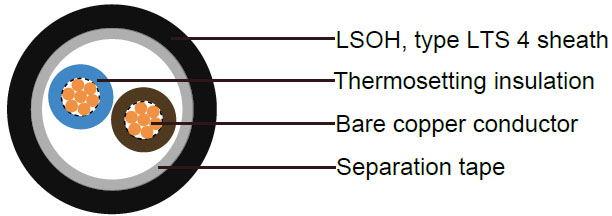

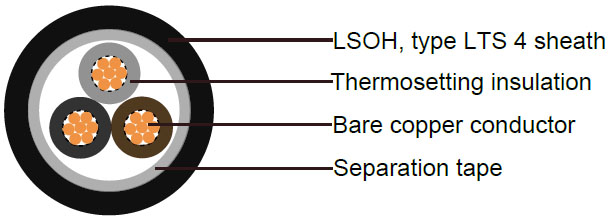

Thermosetting insulated, twin, 3-core, 4-core and 5-core circular sheathed cables

Application and Description :

- These cables are designed for fixed wiring purposes in domestic and industrial power/lighting applications. Can be used in trunking or conduit, or may be surface mounted when used for earthing. and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is installed.

Cable Construction :

- - Fine bare copper strands

- - Strands to IEC 60228 Cl-1 or 2

- - Thermosetting core insulation type EI5 or GP 8

- - The cores shall be twisted together. A centre filler may be used.

- - The twisted core shall be covered by an extruded inner covering or separating tape

- - LSOH sheath, type LTS 4

-

Insulation Colour :

- Twin: brown and blue

- 3-core: brown, black and grey

- 4-core: blue, brown, black and grey

- 5-core: green/yellow, blue, brown, black and grey

Technical Characteristics :

- - Working voltage: 450/750v

- - Test voltage: 2500 volts

- - Flexing bending radius: 15 x Ø

- - Static bending radius: 10 x Ø

- - Flexing temperature: -25º C to +90º C

- - Short circuit temperature: +250º C

- - Flame retardant: IEC 60332.1

- - Insulation resistance: 10 MΩ x km

- - Smoke density acc. to EN 50268 / IEC 61034

- - Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

- - Flame test: flame-retardant acc. to EN 50265-2-1, IEC 60332.1

Cable Parameter :

- Two Cores

-

AWG No. of Cores x Nominal Cross Sectional Area Nominal thickness of insulation Nominal thickness of inner covering Nominal thickness of sheath Nominal overall diameter Nominal Weight Minimum insulation resistance at 90 °C # x mm² mm mm mm mm kg/km MΩ·km 17 2 × 1.0 0.7 0.4 1.2 7.9-9.5 94 0.011 17(7/26) 2 × 1.0 0.7 0.4 1.2 8.1-9.7 110 0.011 16 2 × 1.5 0.7 0.4 1.2 8.4-10.1 121 0.011 16(7/24) 2 × 1.5 0.7 0.4 1.2 8.5-10.3 132 0.010 14 2 × 2.5 0.7 0.4 1.2 9.1-11.0 165 0.0092 14(7/22) 2 × 2.5 0.7 0.4 1.2 9.3-11.3 178 0.0084 12 2 × 4.0 0.7 0.4 1.2 10.0-12.1 212 0.0077 12(7/20) 2 × 4.0 0.7 0.4 1.2 10.3-12.4 232 0.0070 10 2 × 6.0 0.7 0.4 1.2 10.9-13.2 272 0.0065 10(7/18) 2 × 6.0 0.7 0.4 1.2 11.3-13.7 302 0.0059 8 2 × 10 0.7 0.4 1.4 12.9-15.5 446 0.0053 8(7/16) 2 × 10 0.7 0.6 1.4 13.8-16.7 490 0.0047 6(7/14) 2 × 16 0.7 0.6 1.4 15.6-18.8 674 0.0039 4(7/12) 2 × 25 0.9 0.8 1.4 19.2-23.2 1040 0.0039 2(7/10) 2 × 35 0.9 0.8 1.6 21.5-26.0 1130 0.0034 - Three Cores

-

AWG No. of Cores x Nominal Cross Sectional Area Nominal thickness of insulation Nominal thickness of inner covering Nominal thickness of sheath Nominal overall diameter Nominal Weight Minimum insulation resistance at 90 °C # x mm² mm mm mm mm kg/km MΩ·km 17 3 × 1.0 0.7 0.4 1.2 8.3-10.0 110 0.011 17(7/26) 3 × 1.0 0.7 0.4 1.2 8.8-10.2 128 0.011 16 3 × 1.5 0.7 0.4 1.2 8.8-10.6 143 0.011 16(7/24) 3 × 1.5 0.7 0.4 1.2 9.0-10.9 156 0.010 14 3 × 2.5 0.7 0.4 1.2 9.6-11.6 198 0.0092 14(7/22) 3 × 2.5 0.7 0.4 1.2 9.8-11.9 213 0.0084 12 3 × 4.0 0.7 0.4 1.2 10.5-12.7 260 0.0077 12(7/20) 3 × 4.0 0.7 0.4 1.2 10.8-13.1 282 0.0070 10 3 × 6.0 0.7 0.4 1.2 11.8-14.0 351 0.0065 10(7/18) 3 × 6.0 0.7 0.4 1.4 12.4-15.0 387 0.0059 8 3 × 10 0.7 0.6 1.4 14.0-16.9 557 0.0053 8(7/16) 3 × 10 0.7 0.6 1.4 14.6-17.5 607 0.0047 6(7/14) 3 × 16 0.7 0.6 1.4 16.5-19.9 850 0.0039 4(7/12) 3 × 25 0.9 0.8 1.4 20.4-24.7 1315 0.0039 2(7/10) 3 × 35 0.9 0.8 1.6 22.9-27.6 1562 0.0034 - Four Cores

-

AWG No. of Cores x Nominal Cross Sectional Area Nominal thickness of insulation Nominal thickness of inner covering Nominal thickness of sheath Nominal overall diameter Nominal Weight Minimum insulation resistance at 90 °C # x mm² mm mm mm mm kg/km MΩ·km 17 4 × 1.0 0.7 0.4 1.2 8.9-11.2 130 0.011 17(7/26) 4 × 1.0 0.7 0.4 1.2 9.5-11.5 150 0.011 16 4 × 1.5 0.7 0.4 1.2 9.5-11.4 170 0.011 16(7/24) 4 × 1.5 0.7 0.4 1.2 9.7-11.7 185 0.010 14 4 × 2.5 0.7 0.4 1.2 10.4-12.6 240 0.0092 14(7/22) 4 × 2.5 0.7 0.4 1.2 10.6-12.8 256 0.0084 12 4 × 4.0 0.7 0.4 1.2 11.4-13.8 330 0.0077 12(7/20) 4 × 4.0 0.7 0.4 1.2 11.6-14.0 344 0.0070 10 4 × 6.0 0.7 0.4 1.4 13.0-15.7 445 0.0065 10(7/18) 4 × 6.0 0.7 0.6 1.4 13.8-16.7 490 0.0059 8 4 × 10 0.7 0.6 1.4 15.2-18.4 687 0.0053 8(7/16) 4 × 10 0.7 0.6 1.4 15.9-19.2 747 0.0047 6(7/14) 4 × 16 0.7 0.6 1.4 18.0-21.8 1055 0.0039 4(7/12) 4 × 25 0.9 0.8 1.6 22.7-27.5 1670 0.0039 2(7/10) 4 × 35 0.9 1.0 1.6 25.4-30.7 2044 0.0034 - Five Cores

-

AWG No. of Cores x Nominal Cross Sectional Area Nominal thickness of insulation Nominal thickness of inner covering Nominal thickness of sheath Nominal overall diameter Nominal Weight Minimum insulation resistance at 90 °C # x mm² mm mm mm mm kg/km MΩ·km 17 5 × 1.0 0.7 0.4 1.2 9.6-11.5 157 0.011 17(7/26) 5 × 1.0 0.7 0.4 1.2 10.2-11.9 183 0.011 16 5 × 1.5 0.7 0.4 1.2 10.2-12.3 208 0.011 16(7/24) 5 × 1.5 0.7 0.4 1.2 10.5-12.6 227 0.010 14 5 × 2.5 0.7 0.4 1.2 11.2-13.6 295 0.0092 14(7/22) 5 × 2.5 0.7 0.4 1.2 11.5-13.9 317 0.0084 12 5 × 4.0 0.7 0.4 1.4 12.8-15.5 422 0.0077 12(7/20) 5 × 4.0 0.7 0.6 1.4 13.6-16.4 460 0.0070 10 5 × 6.0 0.7 0.6 1.4 14.5-17.5 551 0.0065 10(7/18) 5 × 6.0 0.7 0.6 1.4 15.0-18.1 610 0.0059 8 5 × 10 0.7 0.6 1.4 16.5-20.0 858 0.0053 8(7/16) 5 × 10 0.7 0.6 1.4 17.3-20.9 937 0.0047 6(7/14) 5 × 16 0.7 0.8 1.4 20.0-24.2 1328 0.0039 4(7/12) 5 × 25 0.9 1.0 1.6 25.2-30.5 1860 0.0039 2(7/10) 5 × 35 0.9 1.0 1.6 27.8-33.6 2500 0.0034