Flame Retardant RG6 A/U CWB/SWB/SWA Armoured Coaxial Cables

APPLICATION

These 75Ω coaxial cables are suitable for installation on board of ships and other indoor marine environments.

STANDARDS

- Basic design adapted to MIL-C-17

FIRE PERFORMANCE

| Flame Retardance (Single Vertical Wire Test) |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

| Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1);CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

| Halogen Free |

IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1; BS 6425-1* |

| No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

| Minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2;CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

| No Toxic gases |

NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

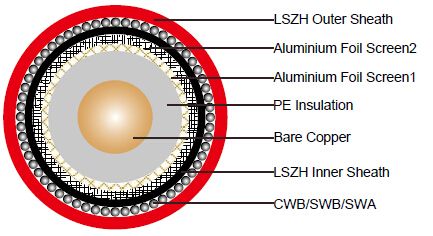

CABLE CONSTRUCTION

| Conductors |

18AWG bare copper wire, solid according to IEC 60228 class 1 |

| Insulation |

PE compound |

| Overall Screen 1 |

Aluminium foil |

| Overall Screen 2 |

Aluminium foil |

| Inner Sheath |

Thermoplastic LSZH compound |

| Armouring |

CWB:Copper Wire Braid

SWB:Steel Wire Braid

SWA:Steel Wire Armour |

| Outer Sheath |

Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH compound type SW2-SW4 as per BS 7655:section 2.6 can be offered.). UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option |

PHYSICAL AND THERMAL PROPERTIES

| Temperature Range |

-30°C - +75°C |

| Minimum Bending Radius |

15 X Overall Diameter |

ELECTRICAL PROPERTIES

| Impedance |

75±5Ω |

| Capacitance |

54 nF/km |

| Velocity ratio |

82% |

| Insulation resistance |

>5000 Mohm.Km |

| DC resistance |

|

| Inner conductor |

23.1 Ω/km |

| Outer conductor |

31 Ω/km |

ATTENUATION

| Frequency |

Attenuation |

Attenuation |

| MHz |

dB/100 m |

dB/100ft |

| 50 |

5.0 |

1.5 |

| 100 |

6.4 |

1.96 |

| 200 |

9.2 |

2.8 |

| 500 |

14.5 |

4.4 |

| 600 |

15.9 |

4.9 |

| 800 |

17.7 |

5.4 |

| 1000 |

21.9 |

6.7 |

| 1350 |

24.9 |

7.6 |

| 1750 |

29.0 |

8.8 |

| 2050 |

33.1 |

10.1 |

| 2400 |

36.4 |

11.1 |

RETURN LOSS

| Frequency |

Return Loss |

| MHz |

dB |

| 30-300 |

>28dB |

| 300-600 |

>24dB |

| 600-900 |

>22dB |

CONSTRUCTION PARAMETERS

| Cable Code |

Nominal Inner Conductor Diameter |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Diameter |

Nominal Weight |

| |

mm |

mm |

mm |

mm |

kg/m |

| RG6/U LH CWB |

1.0 |

1.8 |

1.2 |

10.8 |

181 |

| RG6/U LH SWB |

1.0 |

1.8 |

1.2 |

10.8 |

177 |

| RG6/U LH SWA |

1.0 |

1.8 |

1.2 |

11.8 |

267 |