Flame Retardant Tight Buffered Distribution Fiber Optic cables

MTA-B-C-D-H

APPLICATION

This cables are used for interconnection of distribution boxes and end devices, where continued functionality is required during a fire situation. The cables are very suitable for various indoor and outdoor applications, including routing between buildings within ducts and inside building up to riser shafts.

|

|

STANDARDS

- Basic design to Telcordia GR409-CORE/TIA/EIA 568B.3/ICEA-S-83-596

FIRE PERFORMANCE

| Flame Retardance (Single Vertical Wire Test) | EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

| Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1);CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

| Halogen Free | IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1; BS 6425-1* |

| No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

| Minimum Smoke Emission | IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

| No Toxic gases | NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

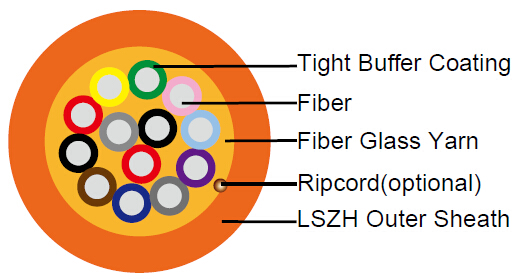

CABLE CONSTRUCTION

| Optical fibers | Singlemode and multimode tight fibers, with tight buffer coating |

| Reinforcement | Either aramid yarn or fiber glass is wound around the tube to provide physical protection and tensile strength, with added fire protection |

| Inner Sheath(optional) | Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 |

| Ripcord(optional) | An optional ripcord can be located under the outer sheath to facilitate jacket removal |

| Armouring(optional) | STA: Corrugated steel tape armour SWB:Steel wire braid |

| Outer Sheath | Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH compound type SW2-SW4 as per BS 7655-2.6 can be offered.). UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option |

PHYSICAL AND THERMAL PROPERTIES

| Temperature range during operation | -30°C - +70°C |

| Temperature range during storage | -50°C - +70°C |

| Minimum Bending Radius | 10 x Overall Diameter (unarmoured cables); 20 x Overall Diameter (armoured cables) |

CONSTRUCTION PARAMETERS

| Cable Code | N° of Fibers | Nominal Overall Diameter | Max. Tensile Strength | Minimum ending adius | Approx.Weight |

|---|---|---|---|---|---|

| mm | N | mm | kg/km | ||

| MTA-B-2-0-H | 2 | 7,6 | 250 | 76 | 55 |

| MTA-B-4-0-H | 4 | 7,8 | 250 | 78 | 67 |

| MTA-B-6-0-H | 6 | 8,6 | 400 | 86 | 77 |

| MTA-B-8-0-H | 8 | 8,8 | 400 | 88 | 81 |

| MTA-B-12-0-H | 12 | 9,3 | 400 | 93 | 90 |