NTSCGEWOEU Medium Voltage Torsion Resistant Cable 12~35kV

Application

These cables are specifically designed for carrying medium voltage energy from the transformer in the nacelle to the bottom of the tower.

Standards

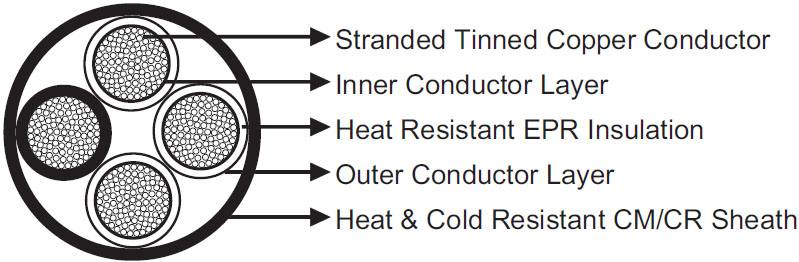

Construction

| Conductor |

Stranded tinned copper, class 5 according to DIN VDE 0295/IEC 60228 |

| Inner Conductor Layer |

Semiconductive rubber compound |

| Insulation |

Heat resistant EPR |

| Outer Conductor Layer |

Semiconductive rubber compound |

| Sheath |

Heat and cold resistant special rubber compound based on CM (Chlorinated synthetic

rubber) or CR (Chloroprene rubber) |

Technical Data

| Rated Voltage U0/U (Um) |

12/20kV, 18/30kV, 20/35kV |

| Operating Temperatures |

-40℃~+90℃ |

| Minimum Bending Radius |

10×OD |

| Torsion Application |

+/100°/m |

| Maximum Permissible Tensile Load |

20N/mm^2 |

| Short-circuit Temperature |

200℃ |

| Flame Retardant |

DIN EN 502652-1/IEC 60332-1 |

| Oil Resistant |

Yes |

| Ozone Resistant |

Yes |

| UV Resistant |

Yes |

Dimensions and Weight

12/20kV

| Construction |

Nominal Overall Diameter |

Nominal Weight |

| No. of cores×mm^2 |

mm |

kg/km |

| 3×25/25 |

61.2 |

4780 |

| 3×35/35 |

65.9 |

5700 |

| 3×50/50 |

69.5 |

6630 |

| 3×70/70 |

73.5 |

7840 |

18/30kV

| Construction |

Nominal Overall Diameter |

Nominal Weight |

| No. of cores×mm^2 |

mm |

kg/km |

| 3×25/25 |

79.1 |

7520 |

| 3×35/35 |

80.5 |

8050 |

| 3×50/50 |

83.1 |

8920 |

| 3×70/70 |

89.0 |

10600 |

20/35kV

| Construction |

Nominal Overall Diameter |

Nominal Weight |

| No. of cores×mm^2 |

mm |

kg/km |

| 3×25/25 |

86.2 |

8820 |

| 3×35/35 |

90.8 |

10000 |

| 3×50/50 |

93.0 |

10830 |

| 3×70/70 |

96.1 |

12050 |